Precision Manufacturing Services

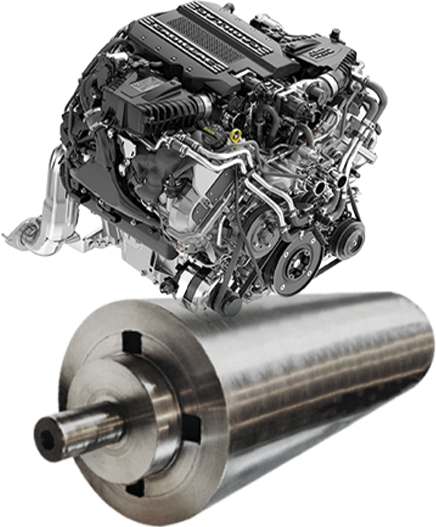

CNC Pattern Making, Progressive Die Making, Aluminum Sand Casting, and Blanchard & Roll Grinding Services

Founded in 1946, Seilkop Industries, Inc. consists of four operating divisions that provide fully integrated design, prototyping, production and finishing solutions.

FOUNDRY, TOOLING, THE DESIGN SIMULATION & BUILDING OF PATTERNS, MOLDS, CORE BOXES & MORE

PROGRESSIVE & TRANSFER DIE MAKING, PRODUCTION READY TOOLING, & IN-HOUSE DESIGN & ENGINEERING SERVICES

OXY FUEL CUTTING AND BLANCHARD GRINDING, LARGE ROLL AND JOURNAL REPAIR, AND PRECISION DIE SETS

Custom Manufacturing Project Showcase

Seilkop Industries, Inc. is the parent comapny of four subdivisions – Hitech Shapes & Designs, A-G Tool & Die, Epcor Foundry, and Hamilton Prevision LLC. Founded in 1946, we provide solutions for Aluminum Sand Casting & Rapid Prototype Casting, CNC Pattern Making & Mold Deisgn & Manufacturing, Progressive Die Making & Transfer Die Making, and Burnouts, Blanchard Grinding, Roll Grinding & Crossley Press. We have detailed case studies for each of our capabilities.

Don’t take our word for it, we let the data speak for itself!

Let's Discuss Your Project

Our Associations

Seilkop Divisions

Contact Us

-

425 North Bend Road

Cincinnati, Ohio 45216 - 513-633-9274

- [email protected]