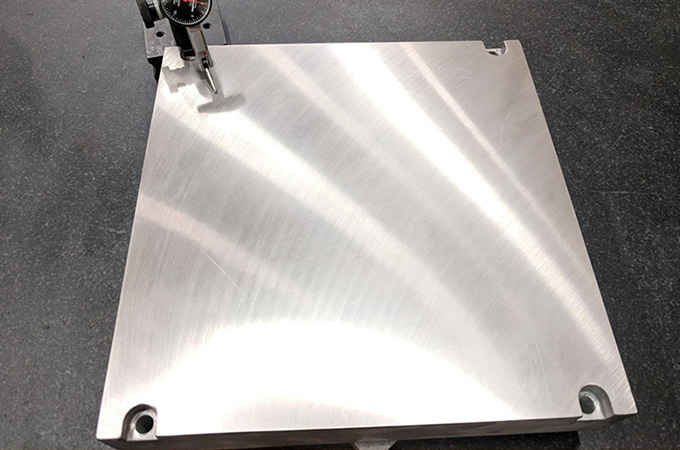

OXY FUEL CUTTING / BLANCHARD / SURFACE GRINDING

Hamilton Precision, LLC a Division of Seilkop Industries, Inc. offers oxy fuel-cutting, Blanchard grinding and surface grinding services and we are proud to work with industries ranging from aerospace to paper. Our processes are appropriate for a variety of intended applications, including A36 burnouts, weldments, rotors, die plates and parallel sets, and stress relieved parts. We can accommodate large sizes during cutting and grinding. Working primarily with mild steel and customers’ material, we feature a 6-1/2 inch maximum cutting thickness, a 96 inch maximum cutting width, and a 240 inch maximum cutting length. For grinding, we feature a length and width maximum of 96 inches corner to corner.

With a burn and grind quote turn-around of less than one day and a lead time of 3 to 7 days, depending on the application, Hamilton Precision, a Division of Seilkop Industries, Inc. is committed to getting the job done-and done well. We can hold a tolerance of up to +/- .001 inches on surface grinding, and can meet customer specified tolerances. We offer value added machining services including, but not limited to, milling, drilling and tapping, counterboring, and welding. To learn more about oxy fuel-cutting and Blanchard and surface grinding with Hamilton Precision, a Division of Seilkop Industries, Inc. please contact us.

WE MACHINE YOUR PLATES & PLATFORMS BACK TO BUILD-READY BY:

- Removing excess material from build plates & platforms

- Grinding the plate surface to be flat again

With our vertical machining center, Blanchard and surface grinding capabilities… HAMILTON PRECISION, a Division of Seilkop Industries, Inc. CAN HANDLE THE ENTIRE JOB!

WITH EXPERIENCED TECHNICIANS AND EXCEPTIONAL CAPABILITIES,

YOU CAN TRUST HAMILTON PRECISION, a Division of Seilkop Industries, Inc. WITH YOUR ROLLS AND SHAFTS.

- Large Grinding Capacity up to 40″ x 240′ and over 10,000 lb (min 16″)

- Tight Tolerances 11- .001″

- Smooth Profile or Concave Grinds — to your surface finish requirements (20 Ra & up)

- Bronze, Hastelloy, Steels, Urethane & Rubber

OXY FUEL CUTTING & BLANCHARD PROJECT SHOWCASE

- Blanchard Ground Frame Plate Burnout for Printing Press Manufacturer

- Oxy Fuel Cutting of Lower Die Shoe with Three Scrap Ramps

OXY FUEL CUTTING & BLANCHARD / SURFACE GRINDING CAPABILITIES

| General Capabilites |

Contract OEM |

|

| Industry Focus |

Aerospace Agricultural Automotive Energy Marine |

Manufacturing Military/Government Mining Pulp and Paper Die Set Manufacturing |

| Intended Application |

Annealed Parts Base Plates Bolster Plates Burn Scrap Ramps Burn Slotted Feet Extractor Plates Heavy Equipment Machine Shops |

Mold Bases Parallels Rotors Stress Relived Parts Sub-Plates Tool & Die Weldments |

| Intended Cutting/Grinding Materials |

Mild Steel Free Machining Steel

|

|

| Cutting Action Type | CNC | |

| Cutting Axis | 2-Axis | |

| Production Volume |

Min .250 in. 6.35 mm |

|

| Cutting Thickness |

Min 1 unit Low Volume to Mid Volume |

|

| Cutting Width |

Max (Cutting - Width) 96 in. 2438.4 mm |

|

| Cutting Length |

Max (Cutting - Length) 240 in. 6096 mm |

|

| Weight Limit |

Max 15 Tons |

|

| Tolerances (+/-) |

Burning: Thickness: 1/4" to 1", 1 1/8" to 3", 3 1/8" to 6", 6 1/4" Square: 1/6", 1/16", 1/8", 3/16" Dimensional Sizes: 1/16", 1/8", 1/8", 1/4" Grinding: Rotary up to 96" corner to corner: W/I .005 Horizontal-maximum size (20" x 70" Table) W/I .001 |

|

| Standard Flatness Tolerances (+/-) |

Thickness: 1/4" - 13/16", 7/8" - 1 1/2", 2 1/6" - 4", 4 1/4" & over Tolerance Per Foot: .006', .004', .003', .002', .001' |

|

| Typical Lead Times Available |

Min 3 Days Quoted on a Job by Job Basis |

Max 7 Days |

| Equipment |

Thompson Surface Grinder: 20" x 70" Horizontal Blanchard Grinder: 96" Corner to Corner Burny Phantom 100" x 100" Table: 2 Torch |

CNC Control Oxy-Fuel Cutter: 4 Torch Burny 100" x 50 Water Table AWEA Vertical Machining Center: 43" x 78" Table 40 Tools |

| Secondary Services |

CAD Drawing CAM Programming Inspection: Full line of calibrated Calipers and Micrometers |

Reverse Engineering |

| Industry Standards |

ASME American Society of Mechanical Engineers ASTM American Society for Testing and Materials |

Mil-Spec Military Specifications |

| File Formats |

AutoCAD Software utilized AutoCAD (DWG, DWZ) DXF |

JPG or JPEG |